Paneer Processing Plant

Paneer Processing Plant

We are offering Paneer Processing Plants that are widely installed in dairy plants and food industries. Our Processing Plants are constructed using stainless steel and are tested thoroughly on stringent parameters.

• Coagulation Vat

We have precise design and low maintenance cost for Coagulation vat. The offered vat is available in various sizes. High-grade basic materials are utilized along with contemporary production equipment to design the entire range and the features, Rugged construction, Low maintenance cost, Durability.

Specifications:

- Capacity of working: Ranging from 500 Litres. To 2000 Litres.

- Shape of vessel: Cylindrical with loose top

- Material of shell & bottom: SS304/SS316

- Accessories fitted: SS304/SS316, Outlet valve

• Paneer Press

Paneer press with Hoops (Either Manual or Pneumatically with Single /Double Head). Paneer Press is used to press the paneer depending upon the moisture and texture required in paneer utilizing optimum quality basic material and advanced technology. The press is rigorously tested on various parameters, in tune with industry standard, we provide the entire range in various specifications, as per the ever-evolving requirement of our clients. Full Stainless-Steel Paneer square box made in 1.6 mm thick sheet with 5 mm SS Plate, 25 mm threaded shaft and other parts in SS.

• Pneumatic Paneer Cutting Machine

Aim is to cut paneer pieces into 200 gms from a 5 kg piece. Now the equipment is based on pneumatic system. It is a vertical platform having a box like arrangement at the bottom. The pneumatic system will lift that box up & down causing the vertical movement. Now the main purpose of this mechanism is to cut paneer pieces. For that a frame is attached in the box at bottom. The frame carries thin wires separated at a specific distance. As the mechanism moves up & down, the frame carrying the wires cuts the paneer into the required sizes. Thus, the required sizes of paneer are obtained. This work provides the desired output and the variety of the cuts is done by use of different cutting grid.

Features:

- To increase production rate

- To eliminates power fluctuation

- Simple in construction

- Continuous operation is possible without stopping

- To reduce the wastage of human energy

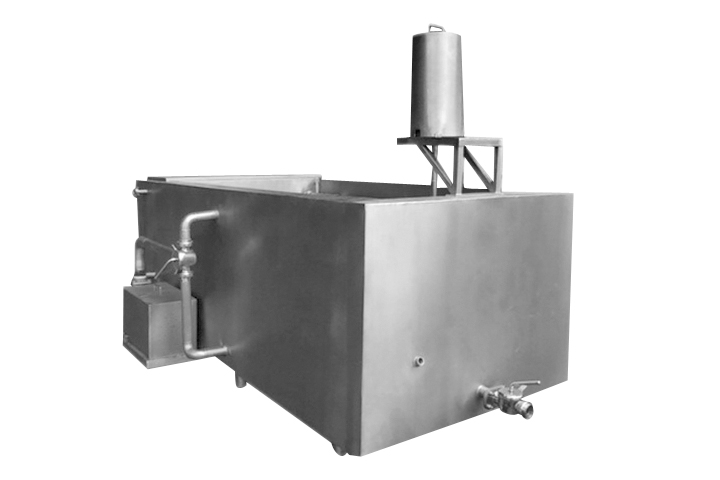

• Paneer Soaking Tank

We Manufacture insulated and uninsulated rectangular tanks with partition plates used as Paneer Cooling Vat. The chilled water is circulated to cool the paneer. Additional skid mounted system to generate chilled water is also provided along with the paneer vat. The system consists of PHE, water pump, water pipeline and inline filter.

#H.No. 33-7-15, Suryalayam Street. TANUKU - 534211, West Godavari District, Andhra Pradesh, INDIA.

+91 94907 15891

© 2023 Copyright