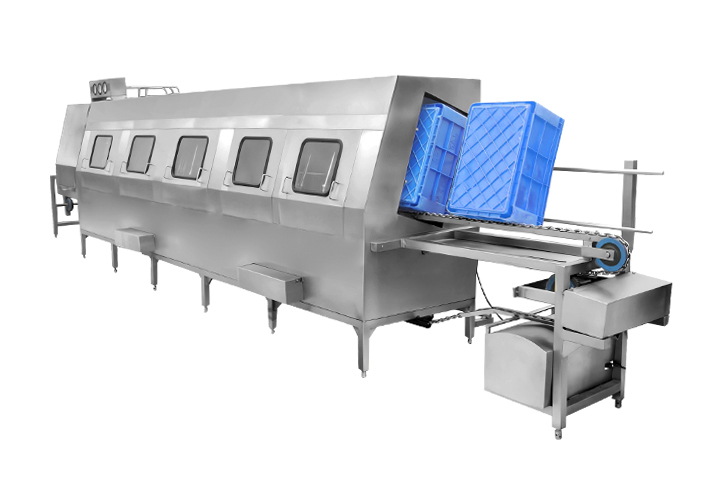

Crate Washer

Crate Washer

The crate washing tunnels have been designed modularly allowing multiple configurations and adjustments for each specific need. The compact and functional design warrantees the cleaning results with the minimum consumption of water, energy, and detergent. According to the requirements, the crate washers can be one or two tracks and can add automation such as distackers, stackers, turners, conveyors, buffers, etc. Currently, hundreds of different crates are used for a wide range of applications: big ones, small ones, nestable, collapsible, etc. You will find the crate washer that fits your needs. Depending on the specific request we can personalize them for the washing of any type of container, from crates and pallets to any kind of tray, RPC, grill, mold, lid, pot, tote…

Industrial crate washing systems are an efficient and effective way of cleaning crates returning from fields, farms, and dairy processing plants. It consists of a main stainless-steel body, synthetic chain conveyor, sprays or click nozzles. The main Body comprises six zones, namely Pre-cleaning, Main Cleaning 1, Reaction, Main Cleaning 2, and Rinsing & Drying. The sixth zone is optional and can be incorporated as per the customer’s requirement. Pre-cleaning as the name suggests, cleans dirt, debris, etc. from the crates, Main Cleaning 1 zone sprays cleaning agent or detergent mixture with water onto the crates at various angles for thorough wetting of all surface area.

The reaction zone allows sufficient residence time for crates so that reaction happens with a cleaning agent and wetted surface area. Main Cleaning 2 zone uses high pressure nozzles to spray water to clean surface area of crates. Rinsing Zone uses hot water jets to make crates hygienic. Drying zone is optional wherein hot air circulated over crates to evaporate water.

#H.No. 33-7-15, Suryalayam Street. TANUKU - 534211, West Godavari District, Andhra Pradesh, INDIA.

+91 94907 15891

© 2023 Copyright