Milk Processing Plant

Milk Processing Plant

We are offering Milk Processing Plants that are widely installed in dairy plants and food industries. Our Processing Plants are constructed using stainless steel and are tested thoroughly on stringent parameters.

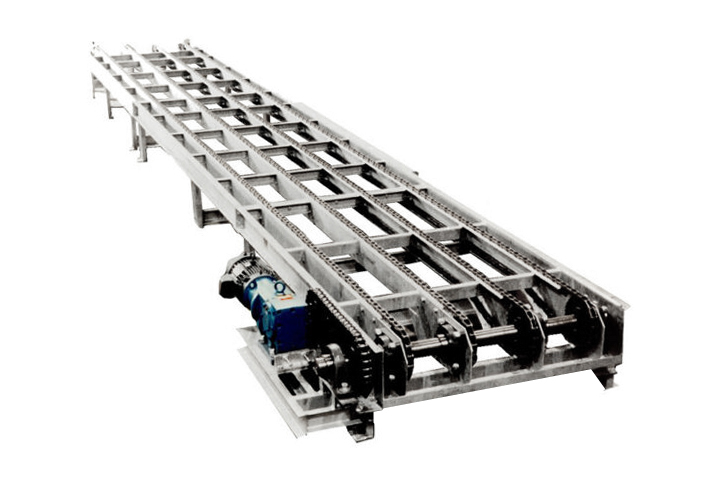

• Motorised Filled Can Loading Conveyor

A conveyor system is a fast and efficient mechanical handling apparatus for automatically transporting loads and materials within an area. This system minimizes human error, lowers workplace risks and reduces labor costs among other benefits. They are useful in helping to move bulky or heavy items from one point to another. A conveyor system may use a belt, screw, wheels, rollers, or a chain to transport objects

Benefits of Conveyor Systems:

- The main purpose of a conveyor system is to move objects from one location to another.

- The design allows for movement of objects that are too heavy or too bulky for humans to carry by hand.

- Conveyor systems save time when transporting items from one location to another.

- As they can be inclined to span multiple levels, they make it simpler to move items up and down floors, a task that, when performed manually by humans, causes physical strain.

- Inclined belts can automatically unload material, eliminating the need for someone to be on the opposite end to receive pieces.

• Motorised Empty Can Loading Conveyor

A conveyor system is a fast and efficient mechanical handling apparatus for automatically transporting loads and materials within an area. This system minimizes human error, lowers workplace risks and reduces labor costs among other benefits. They are useful in helping to move bulky or heavy items from one point to another. A conveyor system may use a belt, screw, wheels, rollers, or a chain to transport objects

Benefits of Conveyor Systems:

- The main purpose of a conveyor system is to move objects from one location to another.

- The design allows for movement of objects that are too heavy or too bulky for humans to carry by hand.

- Conveyor systems save time when transporting items from one location to another.

- As they can be inclined to span multiple levels, they make it simpler to move items up and down floors, a task that, when performed manually by humans, causes physical strain.

- Inclined belts can automatically unload material, eliminating the need for someone to be on the opposite end to receive pieces.

• Gravity Roller Conveyor

A conveyor system is a fast and efficient mechanical handling apparatus for automatically transporting loads and materials within an area. This system minimizes human error, lowers workplace risks and reduces labor costs among other benefits. They are useful in helping to move bulky or heavy items from one point to another. A conveyor system may use a belt, screw, wheels, rollers, or a chain to transport objects

Benefits of Conveyor Systems:

- The main purpose of a conveyor system is to move objects from one location to another.

- The design allows for movement of objects that are too heavy or too bulky for humans to carry by hand.

- Conveyor systems save time when transporting items from one location to another.

- As they can be inclined to span multiple levels, they make it simpler to move items up and down floors, a task that, when performed manually by humans, causes physical strain.

- Inclined belts can automatically unload material, eliminating the need for someone to be on the opposite end to receive pieces.

• Can Tipping Bar

The can tipping bars help in giving support to the milk cans when the milk needs to be taken out. Our range of milk can tipping bars is effective and it is built with the best quality material. The Can tipping bars there comes different benefits:

- The main purpose of a conveyor system is to move objects from one location to another.

- It allows you to transfer the milk with less spill.

- It allows you to hold the milk tank with ease.

- Added support helps the work to be done on time and less stress.

- Premium-grade material that helps your investment will be worth every paisa

• Weigh Bowl with Anti Splash Guard

Stainless steel bowl attached to Electronic weigh scale. May be fitted recording and with automatic weigh recorder. Permits straining, sampling, weighing, recording and dumping of milk.

The milk in cans is dumped into the weigh tank/bowl, of single or double compartment, either manually or mechanically. The stainless-steel weigh bowl of 250 or 500 Kg capacity is attached to a circular dial weigh scale and the portion towards the outlet valve overhangs with anti-splash stainless steel strainer. The outlet valve of weigh bowl is suited for manual or air actuated operation.

• Dump Tank

A dump tank is a vessel with a rectangular cross-section and an open top surface. It is work as a balance tank for milk in between the weigh bowl and milk chiller. Mostly it is used in dairy industries doing continuous milk processing.

After weighing and recording, the milk can be discharged into the dump tank situated below through stainless steel chute between the weigh bowl and dump tank. Dump tank should be of sufficient capacity to avoid delay or overflow of milk, at least one and half times but not more than 3 times the capacity of the weigh bowl. An electronic milk level control may be installed in the dump tank to eliminate the possibility of loss of milk from overflow.

• Can Drip Saver

The can drip saver is sizably used for piling up the milk drips from the emptied cans. We offer a precision engineered can drip saver, which can be controlled both manually and automatically. These are extensively used for collecting milk drips from the emptied cans. These are highly appreciated for their various salient features like easy to operate, longer functional life, and low maintenance. Owing to the unique features, these are widely used in dairy industries. Further, these are available in various specifications and can be customized as per the client’s requirements.

• Can Scrubber

The Can Scrubber is adopted in all milk chilling centres where fewer cans are to be washed. One man can operate this unit conveniently. The scrubber machine is made of 16 swg sheets of stainless sheet. The can scrubber consist of shafts are properly encased in sealed enclosures and provided with suitable bearings and lubrication points. Gland packing is used to avoid leakage through the shaft. A stationary nylon brush is fitted with a bracket on the inner wall for cleaning the outside of the cans. Side stationary brush is changeable and it can be fitted on either side of the inner wall. Cylindrical nylon brushes, revolve at a low speed, i.e.80 to 100 rpm, in opposite directions by a motor and reduction gear unit, giving through an effective cleaning action on either side of the can. Steam and water connection are given to the tank for making warm water for the washing operation. At the bottom of the tank a drain valve is fitted for easy draining and cleaning of the tank.

• Can Lid Opener

This product is used for opening of lid from 40 litre milks can. This lid opener is available in MS / SS. This product is manufactured as per IS:1895. This product is motorised and taper wedge for opening of the lid and is made from PVC/Teflon. Due to this top lid is not damaged. This is simple mechanism. As the name suggested it opens lid of cans automatically without any kind of exertion of pressure over the cans. Its smooth operation and design ensures that the can remain properly spaced on the conveyor and opens lid without any kind of spillage of milk from can. Speed of lid opening from can is synchronized with the speed of can conveyor, so that undue falling off can or malfunctioning of lid opening mechanism is avoided.

Complete operation of can opening is carried out by the operation of eccentric com provided over the shaft which acts as a hammering device to open lids smoothly without any kind of damage to the cans or lids. Can lid opener is grouted to the floor alongside the tray of can conveyor and the guide railing providing guides the can exactly in a position required to open the Lids as they pass along.

• Can Lid Wash Trough

The lid wash trough is completely in SS 304 construction having robust structure. The washing trough is used for washing of machinery parts or Milk Can Lids, Unions, Valves, Dairy Fittings, etc. generally used in Dairy Industries.

• Can Trolley

Can Trolleys are used for conveying Cans from one point to other. Superior quality Polymer wheels have less wear and tear & are non-sticky to the floor. The complete structure is sufficiently heavy enough to bear the load of filled 40/50 Ltrs. Milk Cans. Can Trolley is fabricated with adjustable rib at the rear side by which smaller size Cans, can also be lifted by adjustment.

• SS Plunger

The Milk Can Plunger Stainless Steel is used to shake the Milk. Milk Cans Plunger is widely used in Milk Dairy Industry, Dairy Farms, Milk Collection Centres, Milk Societies, Milk Co-operatives and Milk Plants.

#H.No. 33-7-15, Suryalayam Street. TANUKU - 534211, West Godavari District, Andhra Pradesh, INDIA.

+91 94907 15891

© 2023 Copyright